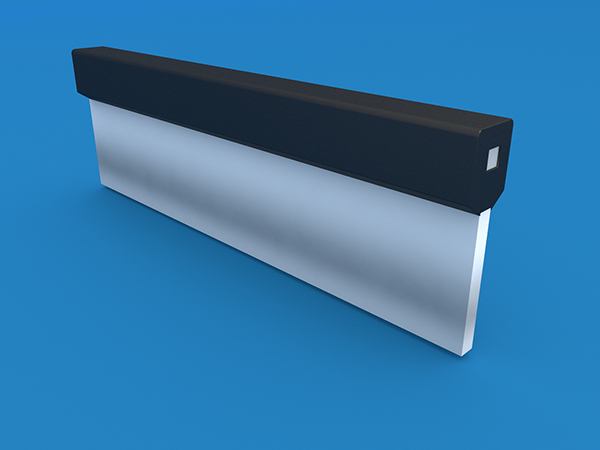

Cathode insulation edge

The benefits can be enhanced by the use of cathode cladding technology. It costs a lot to maintain and replace the cathode insulation edge in electrolysis/production plant. In copper and zinc electrolysis/production plant, cigna's cast insulation edge can save 50-75% of the insulation edge cost every year for a long life. Casting insulation edge can not only save the cost, but also enhance the quality of products. This technology is based on its manufacturing process: drawing, punching, preheating, and forming directly on the edge of the cathode plate. According to the use conditions, materials can be selectively recycled. The V groove at the bottom of the stainless steel cathode plate can be replaced by this technology.